The orientation effect appears in the case of metal bodies in the form of a needle or a thread. In one direction they are detected, but not in the perpendicular direction. Depending on the materials (ferrous and non-ferrous), the effect is opposite.

This implicates that such undesired bodies (for example a metallic thread with a thickness of 1.0 mm and a length of 7 mm) pass undetected. This can lead to dangerous situations.

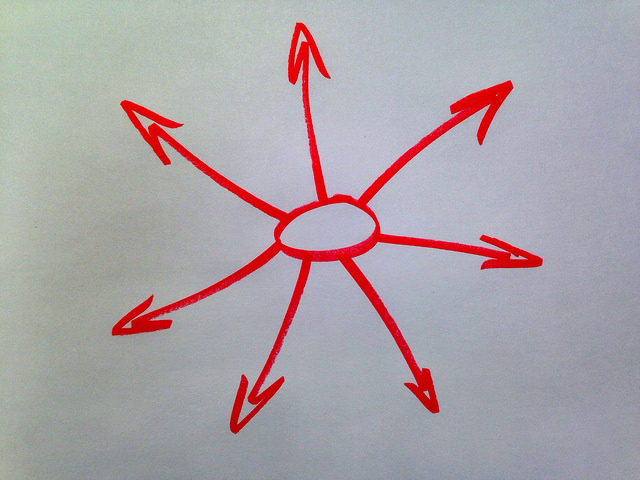

To overcome this, two sensors must be used and placed at right angles to each other. This can be created by installing 2 metal detectors at a 45 ° angle to the production line.

A simple comparison of this effect is the comparison with a sieve. When a needle converges in parallel with the sieve, it will (thankfully) be sieved. It passes easily when arriving on the screen at a 90 ° angle.